INTEGRATED MANUFACTURING EXECUTION SYSTEM

Overview

MES(Manufacturing Execution System) is a system that manages the overall production activities from ordering products to inspecting finished products. It is a system that collects, analyzes, and monitors production processes in real time by collecting various types of information, activities, and equipment operation information.

System Flow

-

01

Work order

-

02

Process input

-

03

Production process

-

04

Quality inspection

-

05

Warehousing / delivery

Features and Advantages

Design is done by standardizing the process for each sector, and functions can be selectively adjusted.

- Decrease inventory holding and see detailed inventory by grasping actual inventory status by process

- Accurate work orders and production systems can be established

- Efficient management of work improvement through real-time defect rate identification

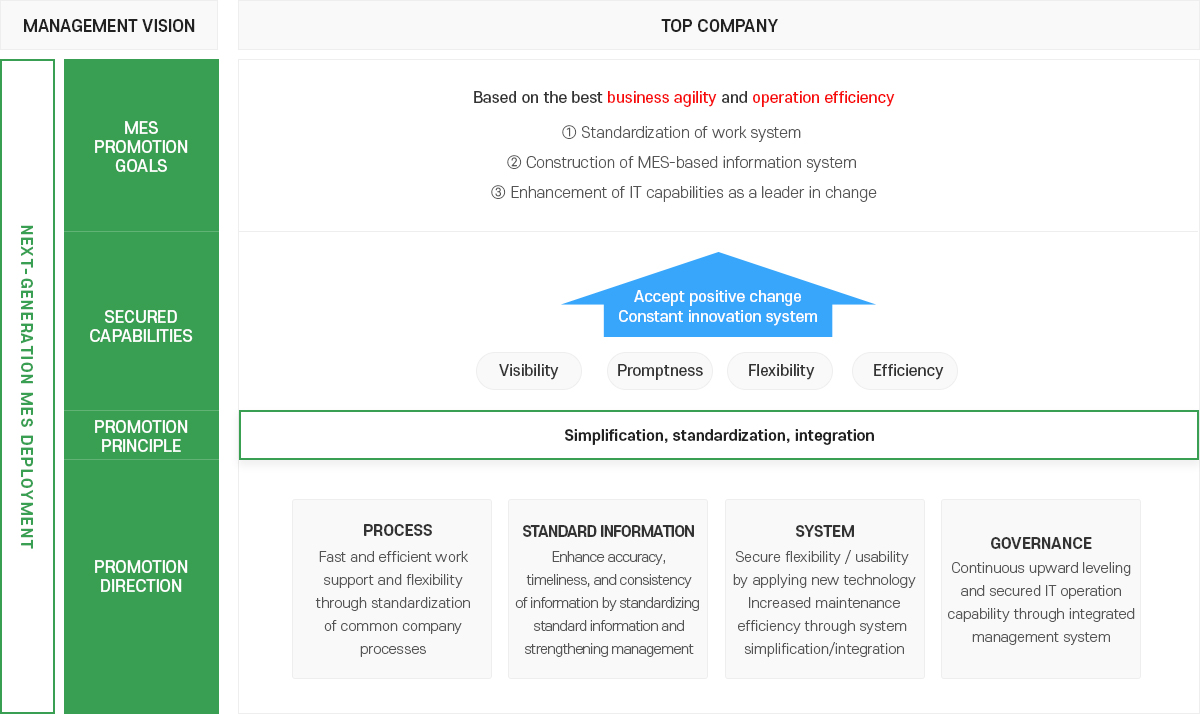

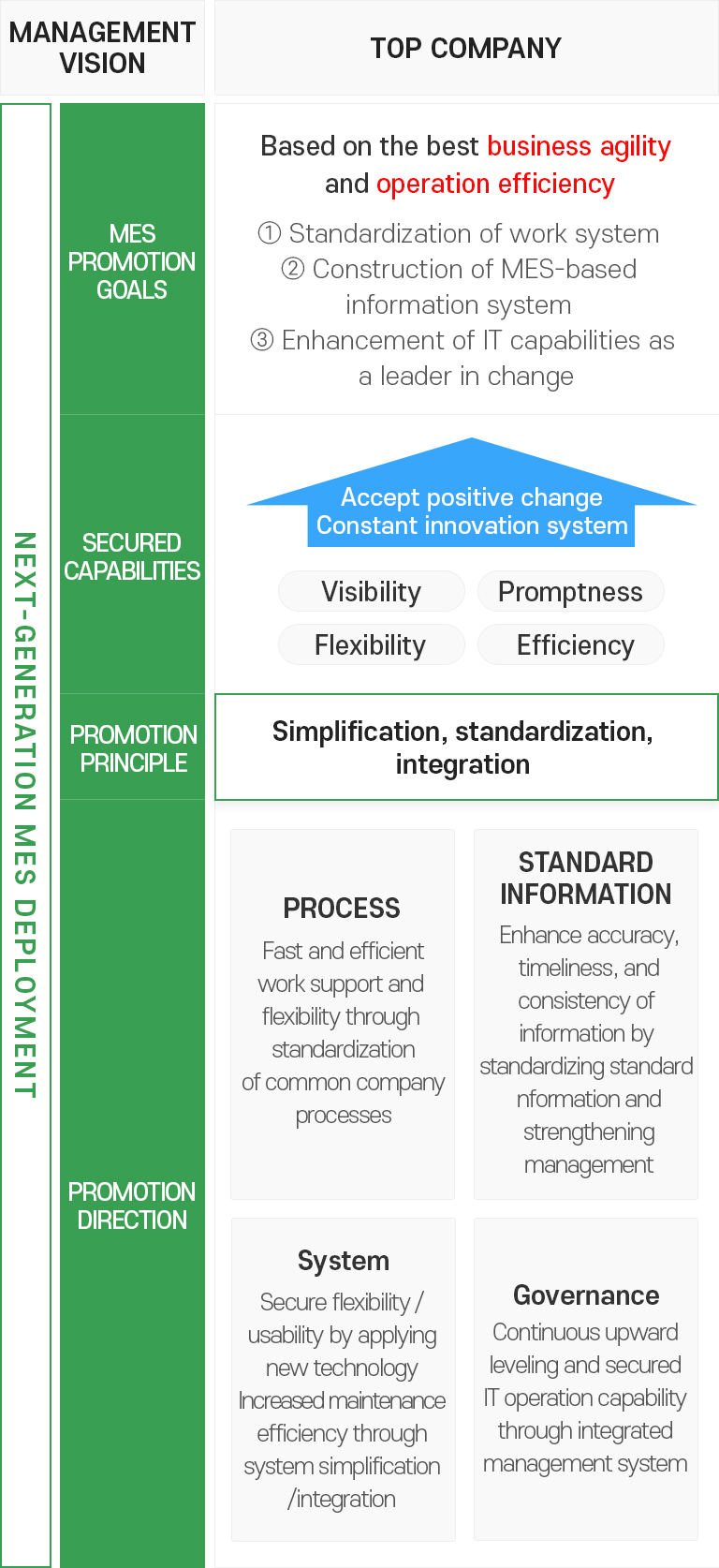

Promotion goals

The goal is to secure continuous competitiveness through MES construction with 1) Creative work processing and 2) Securing a platform of change to eliminate internal inefficiencies.

Expected Effects of Introduction

-

Business operation

- Real-time production information sharing

- Real-time tracking of production information

- Quality information inquiry

- Facility utilization check

- Increased work convenience

- Real-time production information sharing

-

Cost management

- Cost reduction

- Increased productivity

- Improvement of facility utilization rate

- Efficient production planning facilitates resource management

-

Production and management

- Shorter working hours

- Shorten business hours through real-time information utilization and sharing

- Real-time worker performance processing

- Increase worker productivity

- Shorter working hours

-

Cost management

- Secure reliability through quality improvement

- Shorter delivery times and transparent production information

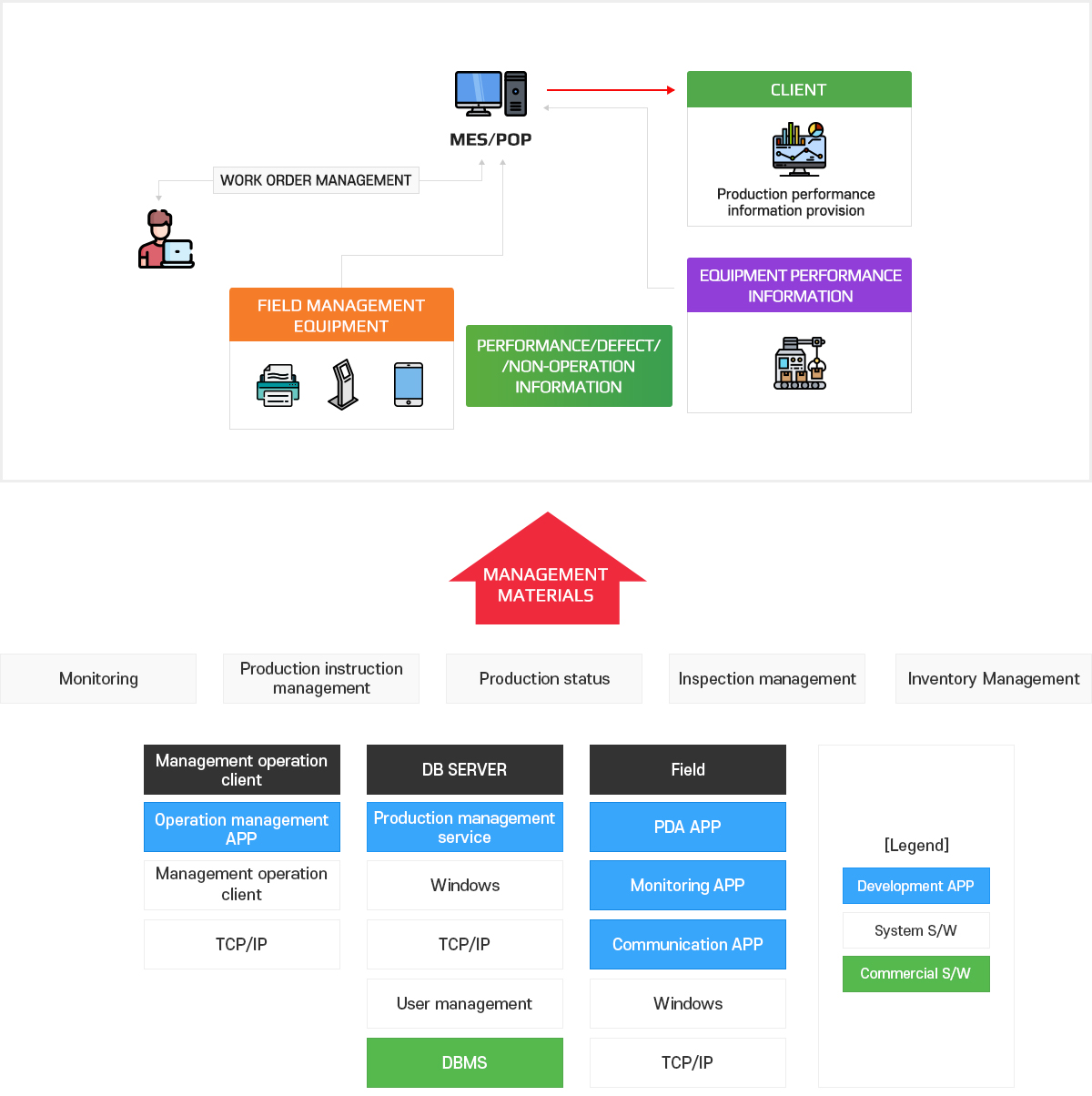

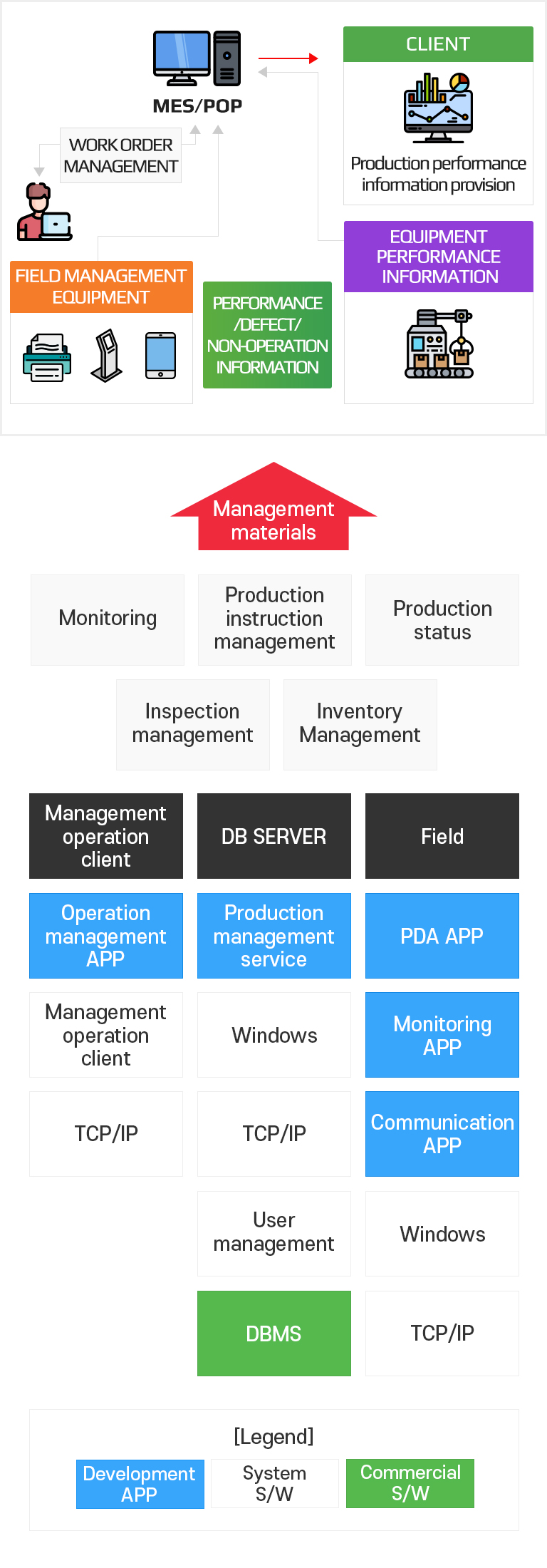

System Configuration

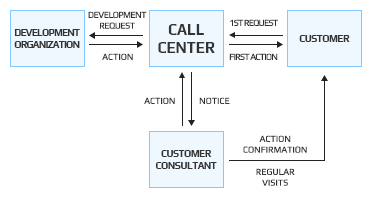

Maintenance Plan

Efficient resource management

Customer relations improvement

System safety

-

Maintenance strategy

- Post management support by the company’s technology expert group and industry experts

- Maintenance support centered on project participants

- Provide one-call service through unified window management

-

Maintenance procedure

- Maintenance target

- Application S/W

- Introduction equipment, system S/W

- Maintenance target

-

Support scope

- Information system operation support (inquiries, education, etc.)

- Evaluation of operation level

- Functional Improvement patch

-

Maintenance method

- Maintenance type

- On Line and On Time Service

- On Time Service (Basic, Silver, Gold, SM method)

- Service center dedicated consultant support

- Maintenance type

-

Service procedure

-

External support

- Introduction H/W, S/W technical support

- Operational technical support

- Performance technical support

- Mutual cooperation with technical support companies

Program Function Configuration

-

Basic management

- Product Code / customer Information

- User code / Faulty code

- Workplace information / facility information

- Process order / Non-operation information

- Defect information / quality information

- System common code

- Authority management

- Menu management

-

Production management

- Work order, production performance management

- LOT history tracking

- Work report by job

- Production defects by period

- Inventory status by period

- Equipment operation status by period

- Performance against plan status

- Hourly, monthly production

-

Production process management

- Factory performance processing

- Defect performance processing

- Daily production defect status

- Production status against plan status

- Work performance by date status

- Production performance by equipment status

- Non-operation by facility status

- Process provision status

-

Production Management

- Equipment maintenance history management

- Equipment spare parts management

- Equipment spare parts use management

- Facility operation rate management

- Operation status by facility

- Non-operation status by facility

- Equipment failure ranking status

- Facility inactivity ranking status

-

Warehousing management

- Barcode issuance (semi-finished product)

- Barcode issuance (product)

- Barcode issuance (return)

- Receipt request

- Receipt inspection

- Receipt confirmation

- Receipt standby management

- Redzone receipt (terminal)

-

Barcode management

- Material in/out

- Product in/out

- Process transfer

- Process inspection

- Physical inventory inquiry

-

Production status monitoring

- Process operation status

- Facility operation status

- Order preparation status

- Inventory status

- Performance against plan status

-

Quality management

- Import process inspection request

- Shipment import inspection request

- Process shipment defect inspection

- Defect status by product

- Inspection equipment interlocking

-

Shipping Management

- Delivery request, inspection

- Confirmation of delivery

- Shipping status

- Daily status

- Shipment transfer status

-

Inventory Management

- Inventory history management

- Cell monitoring

- Status by product

- Long-term inventory status

- Product warehouse monitoring